The Benefits of Upgrading Your Conveyor Equipment for Efficiency

Can you afford frequent breakdowns and high inefficiency of your conveyor system? An upgrade of your system is always advantageous since it considerably changes your operations by increasing efficiency, minimizing downtime, and maintaining continuous operations. Do not hinder the operation of your machines by bowing down to old equipment – embrace the reliability you need!

Improving your conveyor equipment helps to improve the amount that is being moved, reduce the maintenance costs required, and improve the general performance. With the world rapidly turning into an industrial society it has become crucial to stay an important cog in the machine.

This article seeks to take you through some of the benefits that come with upgrading your conveyor system. Here is how it can revolutionize your operations as we continue to see further!

1: Increased Productivity

- It has been seen that improving the conveyor can lead to a substantial increase in throughput. Contemporary systems work at faster speeds and higher accuracy and come with less down and improved material flow rates. This efficiency makes it easier for workers to meet large volumes of work in order, with no extra workforce. Additionally, automated features allow customization for various tasks, such as:

- Automated Sorting: Some of the automation technologies consist of advanced sensors and control systems that can organize items according to size, weight, and or destination to ease distribution.

- Adjustable Speed Controls: Sources indicate that current model conveyors are equipped with speed controls to match the nature of materials and work in progress.

- Safety Enhancements: Anti-stalling devices, halt buttons, barriers, and safety switches help to secure employees and lower the hazards associated with the equipment.

- The execution of these complex features will not only add to the company’s productivity but also reduce risk and enhance efficiency in the workplace.

- sensors

- tracking systems

- adjustable speeds

Material management is an operation-critical factor; only when the material is bought correctly and delivered at the right time can the process excel. It is thus important to consult experts in equipment upgrades such as conveyor roller specialists to realize this goal. For example, they embrace Gram which encompasses every mechanical part of a high-quality conveyor together with its accessories such as the rollers, and belts, among others. They can then help in the specific formation and improvement of conveyor systems to meet particular operational needs.

2:Reduced Operational Costs

Upgrading industrial conveyors can lead to significant long-term cost savings. Modern conveyor systems are engineered with energy efficiency in mind,

incorporating features such as variable-speed drives, low-friction rollers, and energy-efficient motors. These advancements reduce energy consumption, resulting in lower utility bills. Additionally, these systems feature durable components that minimize maintenance expenses. With fewer breakdowns and less wear and tear, businesses experience reduced repair and replacement frequencies, resulting in substantial savings over time.

Enhanced Safety Features:

Safety must be always a top priority consideration in any industry. Old conveyors may have outdated safety standards with the potential for mishaps with workers and or products. Upgrading to a newer system often means integrating advanced safety features such as:

3:emergency stop buttons

1: safety shields:

2: sensors that detect obstructions or jams:

Conveyor systems used today have incorporated ergonomic standards that make them safe for use by workers and implement comfort for the workers. For instance, conveyors can be adjusted to stand height where operators do not have to bend down or stretch out to operate them thus preventing risks of jamming fingers, etc. This not only safeguards workers but also maintains conformity to safety standards and prevents employers from enduring high losses resulting from legal proceedings.

4:Improved Product Quality

Replacing outdated equipment with updated forms of conveyors can greatly improve the existing quality of products as the material flow is optimized. Control systems used in these conveyors are further developed to reduce damage to some products in transit hence improving the quality.

In some industries like the food processing and electronics industries, this improvement results in very limited cases of defects and returns. For example, the application of an automated conveying technique in the manufacturing of foods enhances equal product distribution lowering the probability of contamination and positively affecting the productivity of the output.

In the same way in the production of electronics, the conveyors used are gentle on the sensitive items to avoid breaking them hence producing high-quality products to meet customer satisfaction.

The additional features described here can significantly help companies improve the quality of their products and organizational performance by decreasing returns.

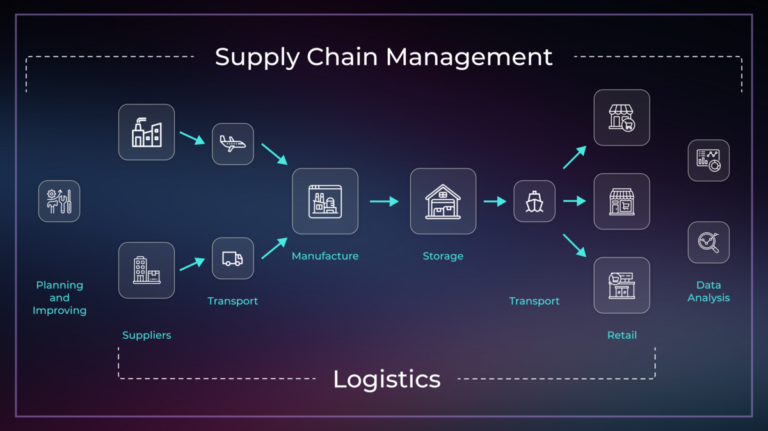

5:Better Integration with Other Systems

Over time the complexity grows because as companies implement more new systems, there is the need for it to interconnect seamlessly with the other business systems. Upgrading your belt conveyors facilitates easier connection with various processes, such as:

- packaging

- sorting

- quality control

Modern conveyors are equipped with smart technology that allows them to communicate with other machinery, including:

1:robots

2:scanners

3:sensors

This allows a completely automatic integrated production system and increased interfacing between the systems.

streamlines operations.

eliminates manual handling.

contributes towards the continuous flow of work.

This applies consistently across the entire production chain.

6:Scalability for Future Growth

The other benefit that you are likely to accrue from investing in better conveyor equipment is scalability. New systems that you implement or install are easy to integrate or upgrade to other systems for business expansion. Whether you need to:

- increase capacity

- accommodate new products

- move materials across longer distances

Today’s conveyors are a long way from the rigid, unidirectional designs of the past. This way, you guarantee that when your company changes and grows its needs, the system is adaptable to the changes as well.

7:Upgrade Your Conveyor Equipment Now

In conclusion, modern conveyor solutions offer high customization. By selecting a system that can be easily upgraded or expanded, you ensure that your investment remains valuable and adapts to your company’s evolving needs.

Therefore, regular upgrading of the conveyor equipment you use is highly beneficial for your business. Don’t wait – place your order today and benefit from a range of improvements that our services provide! Consult with conveyor solution specialists if you are stumped.

.